Facade perchlorovinyl paint: technical specifications and features. Vinyl chloride paint

TYPICAL TECHNOLOGICAL CARD (TTK)

PAINTING THE FACADES OF BUILDINGS WITH CHLORINVIN AND POLYSTYRENE PAINTS

I. GENERAL INSTRUCTIONS

1. The coloring of the facades of stone houses with perchlorovinyl and polystyrene compounds is carried out in accordance with this technological map.

2. Prior to painting, the following must be completed:

a) sandblasting the facade and removing scraping old peeling paint;

b) plaster repair;

c) restoration and installation of stucco products;

g) roofing;

e) repair of external window bindings.

II. RECEPTIONS AND MEANS OF WORK

1. Coloring of building facades with perchlorovinyl and polystyrene paints is carried out in the following order (depending on the type of surface to be painted):

a) inspect the surface before painting and correct the plaster if necessary, clean the surface of dust with a brush or compressed air;

b) paint unplastered facades 2 times without priming with varnish;

c) the facades with newly constructed plaster should be primed with 5% varnish, after which it will be painted 2 times;

g) the facades with partially preserved old plaster should be primed with 5% varnish, put a permanent putty with sanding and painted 2 times.

2. Prime the gypsum façade details with hot, natural drying oil. After the primer has dried, the surfaces of the parts should be coated with 5% varnish and painted 2 times.

3. The wooden surfaces, previously cleaned of dirt and remaining paint, should be primed with a natural drying oil; after drying, varnish should be coated with 5% varnish, puttied, followed by sanding and painted 2 times, adding 5% plasticizer to the paint (dibutylstolate, etc.).

4. Before painting with perchlorovinyl and polystyrene paints, the places previously painted repeatedly with the same paints should be cleaned or primed with alcohol-shellac varnish, polyvinyl acetate paint or 5% solution of casein glue.

5. With an uneven texture of the plaster, partially fill the irregularities, and then solid-over the entire surface.

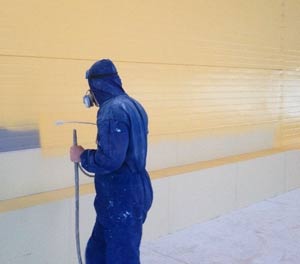

6. Paint the facades with perchlorovinyl and polystyrene paints using spray guns in accordance with the schemes shown in Fig. # M # S and # M # S, or manually (with brushes). Painting in rainy weather or in direct sunlight is prohibited. Breaks in painting should be allowed only at the borders of rods, scraps and other articulations of the facade.

7. When working with spray guns, observe the following instructions:

a) mix the paint before use to a consistency of 30-40 seconds using a VZ-4 viscometer;

b) blow out the hoses and spray gun before painting, adjust the pressure in the tank by 1.5-2 atm .;

c) direct the stream of paint from the spray gun to perpendicular to the surface to be painted; the nozzle of the gun at the time of painting should be at a distance of 40-80 cm from the surface to be painted.

8. Metal structures and parts should not be painted with perchlorovinyl and polystyrene compounds.

9. Work with perchlorovinyl and polystyrene paints in respirators or goggles; Before starting work, grease hands with Vaseline, and after work wash with warm water and soap. Smoking near these colors is prohibited.

10. Store perchlorovinyl and polystyrene paints and their solvents in a closed container under awnings, in inventory cabinets or in well-ventilated rooms at a temperature not exceeding 20 ° C.

11. Putty and paints before using them in the winter time, soak for 2 days in a warm room, insulate the paint pump tank and install it and the compressor on the tiers of the scaffolds to reduce the length of the hoses to 6-8 m; the cylinder block, oil separator and receiver tank of the compressors are also heated. To heat the paints in winter, use special water baths of the design of the Fasadremstroy trust (# Mris. 3 # S).

12. Painting in winter conditions on wooden and metal surfaces with oil compounds cannot be done; these surfaces should be painted 2 times with special compositions that differ from ordinary perchlorovinyl in high resin content and the addition of plasticizers. The formulation of perchlorovinyl and polystyrene compositions is given below.

13. The schemes of the paint-injection tank and the spray gun are shown in Fig. # M # S and # M # S.

14. Work on painting the facades of buildings with perchlorovinyl and polystyrene paints should be carried out with a link of 6 people.

QUALITY CONTROL OF WORK

Surface preparation for painting

The quality of painting and its service life on the facade after the repair of roofing is largely dependent on careful surface preparation before painting. Paint compositions require surface preparation for painting:

1. The surface must be thoroughly cleaned of dirt, fragile flaky old paint (accumulated) and even from strong layers of old paint and putty, if the composition of the new paint requires it.

2. Destroyed, damp, tarry or behind the wall (determined by a dull sound when tapping), the old plaster should be removed and a new one should be made instead. Moreover, the covering layer should be close in texture and size of sand to the covering layer of the preserved old plaster, so that after painting the places with new plaster should not be stained on the facade of the building.

3. The facade should be prevented from efflorescence. For this place, the walls, dampened by leaks, should be dried after removal of the old plaster, the efflorescence should be cleaned and the new plaster should be made of a hydrophobic solution that prevents the penetration of salts into the paint layer. A hydrophobic plaster solution is made from a composition of 1: 0.5: 4 with the addition of a 1% solution of silicone 50% emulsion GKZh -94 in an amount of 1 kg or 12 kg of a 10% solution of soap-oil.

4. In accordance with climatic conditions, when repairing the plaster, frost-resistant mortar compositions of 1: 0.5: 5 by volume (Portland cement: lime paste: sand) should be used. Gypsum and lime-gypsum mortars are durable only in dry conditions, and they are quickly destroyed by accidental leaks and frost, so they should not be used on facades. The use of "greasy" mortar compositions with a large proportion of lime is not recommended, since these solutions, although convenient in operation, give shrinkage cracks in the plaster in the future. When plastering facades, it is not recommended to use lime-slag and lime-pozzolanic mortars, slag Portland cement and pozzolanic Portland cement, as experience has shown that such plaster on the facades quickly collapses. To avoid this, it is recommended to use ordinary Portland cement in complex mortars for plasters. The use of ground quicklime magnesia and dolomite lime in complex solutions leads to cracks in the plaster, to avoid which such lime should be pre-soaked with water two days before use.

Old layers of lime, casein, polyvinyl acetate, perchlorovinyl and polystyrene paints are cleaned off mainly by sandblasting and cleaned with scrapers and brushes. Old layers of oil paint, which cannot always be removed by sandblasting, are removed with steel scrapers using (if necessary) preliminary calcination of the oil accumulated with soldering or gas burners.

Sand for sandblasting should be dry, clean, without clay particles, sifted through a sieve with holes of 1.2-2 mm. Sandblasting is carried out using sandblasting machines with a capacity of 170 l and 250 l. These devices operate using compressed air supplied by a ZIF-55 compressor. The working pressure during cleaning is selected in relation to the state of painting and plaster in such a way that excessive pressure does not cause them to be damaged in places that must be preserved, at the same time, the pressure should be sufficient to remove dirt and unstable deposits. For this, it is usually sufficient to have a working pressure of 2-3 atm. When cleaning the facade, the distance between the nozzle and the surface being cleaned is 0.4-0.8 m.

Dry sand cleaning is accompanied by a large dust formation, in order to avoid what a hydro-sandblast cleaning method has been developed and successfully tested, in which cleaning is carried out with a mixture of sand and water. To do this, the usual nozzle is replaced by a special device (# Mris. 6 # S), which, in addition to the nozzle and hose for sand, has a separate nozzle and hose connected to the domestic water supply. The device works with two nozzles, the water pressure in the network should be at least 0.5 atm. Approximately 5 kg of sand and 5 l of water are consumed per 1 m2 of surface to be cleaned.

When cleaning facades with sandblasting machines, special care must be taken to clean the molded products.

After cleaning the facade from contamination and old plaster, the plaster is repaired. With large volumes of plaster being replaced, it may be appropriate to use a mortar pump to supply the solution to the nozzle. It is advisable to choose such mortar pumps that do not require very liquid solutions, but allow you to work on relatively thick solutions (5-6 cm cone).

The nozzles of the non-compressor type are suitable for applying the solution, which make it possible to exclude fogging and rebound of the solution and making it possible to apply it not only on wide, but also on narrow planes (window and door slopes, drafts, belts and cornices).

The technical staff and the workers themselves must always remember that in the event of a violation of safety requirements, they endanger both themselves and their comrades working with them.

Before starting work, the reliability of installed scaffolding and mounted cradles is checked. Scaffold frames should be completely stable, firmly attached to the wall and have a reliable support; the ends of the decks should be located on the supports; the location of the joints of the flooring and boards between the supports is unacceptable. Floors and stepladders for lifting on them must be enclosed with handrails and (bottom) side boards to prevent slipping of feet and falling materials; There should not be any nails and staples on floors, handrails, racks and steps. Forests should be regularly cleaned of debris, snow and ice. When working on several tiers of forests at once, it is necessary to arrange workers so that they do not simultaneously work on the same vertical (one under the other).

When working with cradles, it is necessary to ensure the strength of ropes, cables and blocks, the reliability of their fastening. In order to avoid damage and disruption of the eaves, the cradle should be hung on special devices (cantilever beams, underlay boards, swing hooks, etc.). Before working on the cradle, it must be tested with a double working load, as well as to check the stability and serviceability of the winch and brake device. Lifting and lowering the cradle with workers in it is allowed only if the cradle itself has a special mechanism for this. When working with cradles, as well as when working on the roof and other places that do not have fences, it is necessary to provide workers with safety belts and ropes tied to strong parts of the building. The place under the cradles near the facade should have a fence.

During operation, all electrified devices and tools are reliably grounded to avoid the possibility of electric shock. All joints of electrical wires are well insulated, wires are suspended on insulators, and not on temporary slats and not on nails; circuit breakers for switching on current and electric fuses are placed in special boxes.

When working on facades near which electric lines are located, special care must be taken: it is strictly forbidden to touch the wires; if fastenings of the contact networks of a tram or trolleybus are attached to the facade, it is impossible to start work until obtaining permission from the tram-trolleybus service and before turning off the current.

When working with mechanisms and devices, all the rules for using them indicated in special instructions must be observed, as well as the following rules:

1. Before starting the mechanism, check its idle operation.

2. Do not clean, lubricate, open or repair the mechanism on the go.

3. Do not work on faulty and unverified control and monitoring devices (pressure reducing valves, pressure regulators, pressure gauges, actuators, etc.), as well as without fencing all moving parts of the drive (transmission belts, gears, etc.).

When working with dusty materials and toxic compounds that are harmful to the skin, mucous membranes and respiratory tract of a person, workers should wear glasses and respirators, lubricate Vaseline face and hands, wear special clothing, shoes and mittens. Work without protective devices against the harmful effects of dust, alkali, acid and other chemically active products is not allowed.

When working with combustible compounds (containing solvent, xylene, kerosene, white spirit, turpentine, etc.), workers should be familiar with fire safety rules before starting work; smoking and using open fire with these compounds is prohibited.

Workers engaged in the repair of facades in winter conditions should be provided with warm clothes (quilted jackets, cotton trousers), shoes (felt boots), warm mittens and be able to periodically be heated in a room designated for this purpose.

If a worker develops nausea, dizziness, headache, and other ailments during work on the facade, he should immediately contact a medical center.

Before eating and at the end of work, the hands and face of the worker should be thoroughly washed.

Persons not younger than 18 years old are allowed to carry out painting work, as well as to prepare paint compositions.

The painter should remember that due to failure to comply with the requirements set out in the instructions for labor protection, the daily routine, when carrying out painting work, dangers may arise:

Electric shock;

Poisoning by pairs of paints;

Falls from a height;

Ignition of paints and varnishes.

The workplace should be organized in accordance with the maps of labor processes, kept clean.

The condition of forests, cradles and towers must comply with the requirements: # MGOST 12.2.003-91 # S, # MGOST #S, # MGOST #S, # MGOST. # S

Hazardous places and areas contain posters and labels for TB.

The painter must:

Perform only the work assigned to him by the work manager;

Smoke and use open flame only in designated areas;

II. Safety Requirements Before You Begin

The painter must:

Get a safety briefing from the work manager in case of a change in the type of work and working conditions, to clarify the task;

Put on and tidy overalls and personal protective equipment;

Inspect the workplace, remove unnecessary items, clear passages;

Check tool health;

If necessary, turn on the lighting;

When using a mechanized tool - make sure that electrical equipment, cables, grounding, hose connections for compressed air are in good condition, and test it at idle;

Check the readiness of paints for use.

III. Safety Requirements During Operation

The painter must:

Do not clutter the aisles and the workplace with building materials, containers;

Use only ready-made colors;

Serve a tool with sharp and sharp surfaces so that the working receiving tool can grab it by the handle.

When working at height:

To store the tool and container after taking measures to prevent their spontaneous fall;

Use tested safety belts;

To go down only on step-ladders or capital stairs;

The painter is FORBIDDEN:

Work without overalls and personal protective equipment;

Work with faulty equipment and tools;

Work in malfunctioning and insufficient lighting;

Do not approach or be under a raised load;

To wedge racks of scaffolding and scaffolding with trimmed boards, bricks and other contingent devices and materials;

To sort forests and scaffolds by the method of collapse;

To carry out work on unshielded workplaces at a height of more than 1 m above the ground;

IV. Safety requirements at the end of work

The painter must:

To tidy up the workplace;

Disconnect from the network mechanisms and electrified tools;

Wash and return to the warehouse removable equipment and tools;

Remove mechanisms from scaffolding and scaffolding.

V. Requirements for the behavior of the worker in the event of a dangerous situation

An emergency situation may occur due to:

Excessive load on forests;

Short circuits and fires of power cables;

Power cuts.

The painter must:

Immediately signal a danger;

Take measures to prevent an accident and leave the danger zone;

Inform the supervisor;

If necessary, provide first aid to victims.

Work Schedule

Table 1

Scope of work |

measuring | Scope of work | Labor input per person according to ENIR | Link composition |

||

profession | quantity |

|||||

Primed the surface of the facade with 5% varnish with a gun- spray gun |

IV category II category | |||||

Continuous filling of the facade with finished putty | ||||||

Grinding the surface of the facade with a pumice stone | ||||||

Painting the facade with perchlorovinyl or polystyrene paint in two | ||||||

Work Schedule

Table 1

continuation

Process Schedule |

|||||||||||||||||||||

Work shifts |

|||||||||||||||||||||

Labor costing given in table 2.

Labor costing

table 2

The basis for the accepted norms on ENiR | Scope of work | unit of measurement | Scope of work | Norm of time in person-hours | Link composition | Price in rubles | number people - hours for the entire amount of work | The cost of the total amount of work |

||||||||||||||||||||||||||||||||||||||||||||||

Primed the surface of the facade with 5% varnish with a gun- Perchlorovinyl and polystyrene compounds for winter conditions (in% by weight) Material and technical resources Table 3

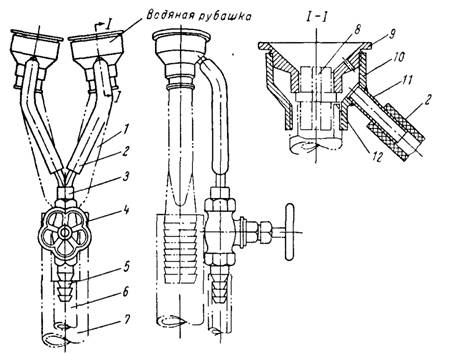

http://pandia.ru/text/78/012/images/image005_44.jpg "width \u003d" 687 "height \u003d" 540 src \u003d "\u003e Fig. 2 . Color distribution scheme for forest tiers, zones and grapples captures; 7 - paint injection tank for painting zone No. 1; 8 - paint injection tank for painting zone No. 2; 9 - compressor Chimneys "href \u003d" / text / category / dimohodi / "rel \u003d" bookmark "\u003e chimney; 5 - slide http://pandia.ru/text/78/012/images/image008_31.jpg "width \u003d" 481 "height \u003d" 621 "\u003e Fig. 5 . Spray gun 1 - nozzle; 2 - nozzle; 3 - spray gun; 4 - case; 5 - handle; 6 - valve for paint; 7 - trigger

Fig. 6 . Facility for sandblasting facades 1 - fitting for sand; 2 - a hose; 3 - tee; 4 - tap for water; 5 - fitting for water; 6 - a hose for water; 7 - a hose for sand; 8 - replaceable tip; 9 - a spray; 10 - water jacket body; 11- tube; 12 - gasket The electronic text of the document has been prepared Codex CJSC and verified against: # M12 General Russian Public Fund "BUILDING QUALITY CENTER" #S st. Petersburg |

- Serious protection against adverse climatic effects (moisture, frost);

- Very high adhesive properties, which reliably protect the walls of the building from moisture penetration;

- The widest range of possible operation - this type of paint can be perfectly applied both to brick, wood or concrete walls, and to any plastered surfaces;

- The ability to carry out work in the conditions of the Russian winter, at sufficiently low temperature indicators. The fact is that perchlorovinyl paint does not thicken even at ultra-low temperatures (below - 15 degrees Celsius).

- Bright, deep and very saturated color, able to maintain its pristine appearance for 2-3 years.

Among disadvantagesperchlorovinyl paint, which every owner should also be aware of, we note the following:

- Inability to paint facades during snowfall or rain. The main condition for the paint to firmly and reliably “seize” with the base is 100% dry surface.

- It is impossible to paint the walls on which direct sunlight falls upon drying. The fact is that ultraviolet dries the paint significantly faster than necessary by technology. This leads to the fact that the paint cracks and falls off. The ideal temperature for painting can be considered 15 - 20 degrees Celsius.

- Low elasticity of the paint is a drawback that has arisen as a result of the inclusion of many pigments in its composition. Keep in mind that any curvature of the facade leads to cracks in the paint layer. For this reason, it is highly advisable to apply perchlorovinyl paint on the surface of an already seated house.

We also note that all the existing drawbacks of paint more than overlap with its most important advantage - its relatively low price. Together with a large number of advantages, it is the low cost that makes this paint an increasingly popular solution for painting facades among Russians.

Perchlorovinyl paint application technology

Like any paint, this type of finishing material requires preliminary surface preparation. Consider the issue of pre-processing the facade in more detail.

- In the case when it comes to painting a new wooden house, it will not be superfluous to treat the walls with antiseptic agents. Then, as they dry, the walls need to be primed - this is done so that the paint goes better.

- In the event that the application of paint is supposed to be on concrete walls that were previously painted, you need to clean them from the old paint using a sandblasting machine or manually, using a metal scraper. Then - how to clean the facade from dirt and dust and cover with a primer.

- In the event that the application of paint is planned on a thermal insulation layer, it is necessary to cover it with a reinforcing mesh in order to strengthen the surface.

Read about how it is done on our portal!

The specifics of working with perchlorovinyl paint

- It is strictly forbidden to mix perchlorovinyl paint with any other type of paint to obtain any color or shade. The choice of color and shade, alas, is limited only by those that the manufacturer offers.

- During paint work, care should be taken to protect hands and eyes from the harmful effects of xylene and solvent vapors, which are part of the paint. To do this, use a protective mask (or glasses) and gloves. It is forbidden to use perchlorovinyl paint indoors!

- Paint can be applied using a spray gun or roller.

Instructions for applying perchlorovinyl paint

The instruction on the application of perchlorovinyl paint is not particularly difficult. Most people have an idea of \u200b\u200bhow to apply paint using a roller. However a few important tips we still allow ourselves. So:

- It is better to start painting work from the very top of the facade. Thus, trickles of flowing paint will gradually be painted over with new layers.

- In the process of staining, circular movements should be avoided. The roller control must be carried out strictly vertically or horizontally.

Video instruction for applying paint

- It is better to apply the paint in two layers (the second layer is applied when the first is completely dry). The paint, sequentially applied in two layers, will hold much stronger and will give the appearance of the facade a brighter color.

- It is advisable to apply paint to a selected section of the wall immediately, without interruption. The fact is that when applying paint in several passes, there is a risk of the formation of noticeable color transitions between the layers.

A few important words about perchlorovinyl paint

In conclusion of the conversation about perchlorovinyl paint, let me tell you about several important nuances that you certainly need to know if you are seriously thinking about acquiring one for painting the facade of your own house.

1. Perchlorovinyl paint consumption. The average paint consumption is approximately 150 - 230 grams per 1 square meter, depending on the type of surface. When applying paint in 2 layers (recommended in all cases), its consumption increases by 2 times and amounts to about 300 - 460 grams per 1 square. meter.

2. GOST. When purchasing goods, make sure that they comply with GOST - 25129-82. Unfortunately, the market is replete with products positioned as “perchlorovinyl paint”, while GOST is either not available at all or has a different label.

3. Life time. According to GOST, the operational life of the paint is at least 10 years. At the same time, the shelf life of the paint (in an unopened can) should not exceed 1 year. After this period, the paint loses its properties and is not recommended for use.

4. Warning! In no case do not store the container with paint at temperatures above 40 degrees Celsius, do not leave the paint in direct sunlight!

We hope that the above material on perchlorovinyl paint will be useful to you.

Perchlorovinyl facade paint is used to decorate exterior surfaces. It is made by dissolving perchlorovinyl in xylene or solvent at a temperature of +70 degrees. When dried, the solvents evaporate, forming on the surface a solid protective and decorative layer with high weather resistance. The coating has good adhesion and protects against moisture penetration into the finish.

PVC facade paints have a high color tone saturation and are able to maintain their decorative properties for 3-4 years. Perchlorovinyl compounds can be used for painting wooden, brick, concrete, plastered or metal facades. They are resistant to strong acids (hydrochloric or acetic), solutions of mineral salts, gasoline and oil.

The main disadvantage is that the volatile components during evaporation emit substances harmful to the human body. Most of these components are flammable, so the use of perchlorovinyl compounds requires additional fire safety measures.

Varieties of perchlorovinyl paints

The exterior decoration uses perchlorovinyl facade paint with a reduced mass of perchlorovinyl varnish and special impurities. The following enamels are most widely used:

1. Enamel XB-125 - a suspension of finely divided aluminum chips and talc in a solution of polyvinyl chloride and alkyd resin with the addition of volatile organic solvents and plasticizers. It is used for painting wooden and metal surfaces. It does not require preliminary priming.

2. Perchlorvinyl facade paint ХВ-161 is a mixture of fillers and pigments dissolved in 10% PVC-varnish. Mass fraction of non-volatiles - 43-47%. It is used for painting plastered and brick facades. It can be applied at air temperatures from -20 to +40 degrees.

3. Paint ХВ-182 - modified enamel with a mass fraction of non-volatile substances 37-46%. The composition has high adhesion and sedimentation stability. It is applied for decorative finishes brick and concrete surfaces. Before applying the facade must be treated with putty and primer on a perchlorovinyl base.

Technical characteristics of perchlorovinyl facade paint

Perchlorvinyl facade paint has the following technical indicators:

- viscosity - 30-45 s, which allows the use of a spray gun and does not require the introduction of diluents;

- milling degree - not more than 30 microns;

- drying temperature - 4 hours;

- covering power - 110-120 g / sq. m;

- paint consumption - not more than 270 g / sq. m with a layer thickness of 25 microns;

- drying time at a temperature of +20 degrees - no more than 24 hours

Features of application and storage of paint

Perchlorovinyl facade paint is available in ready-to-use form. Before use, it is recommended that the paint be kept at room temperature for at least 8 hours. This will reduce the viscosity of the composition and ensure uniform surface coverage.

When decorating the facade perchlorovinyl paint The following rules must be observed:

- Before painting, the surface must be prepared: level, clean, remove old plaster and other lagging coatings.

- To improve adhesion, the facade is covered with a primer based on perchlorovinyl varnish (for example, ХВ-148) and putty (ХВ-0018).

- In the process, the mass must be regularly mixed, since due to the high content of pigments with different densities, the solution begins to delaminate quickly.

- If necessary, the paint may be diluted. As solvents, xylene or solvent is used in an amount not exceeding 10% by weight of the coloring composition.

- The paint must be applied in two layers. The next layer is covered only after the previous one has completely dried.

Paints are stored in hermetically sealed containers at a temperature of not more than 10 degrees in a well-ventilated area. With a loose fit of the lid, the volatile components begin to dissolve quickly, turning the composition into a hardened mass. The enamel has a shelf life of 6 months from the date of its manufacture.

Relatively recently, a new type of paints, which are made on the basis of perchlorovinyl, has appeared on the construction markets. Perchlorovinyl paint is used for outdoor work, so it is often called facade paint. It has so many useful qualities that others cannot boast of. decoration Materials similar kind.

But first things first.

Specifications

Like any material, this one has several varieties that differ in the amount of volatile substances in their composition, as well as the purpose and method of application. I must say that specifications perchlorovinyl paints vary depending on the particular variety.

Classification

So, the main types can be called the following:

- Enamel ХВ-125. It is used for painting exclusively wooden and metal surfaces;

- ХВ 161 perchlorovinyl facade paint. This is a mixture of various fillers and pigments, which are dissolved in 10% PVC varnish. The share of non-volatile substances is about 47%. This type is used for, as well as plastered surfaces;

- Enamel XB-182 is a modified enamel in which the share of non-volatile substances can be as low as 36%. It is used for decorative painting of concrete and brick surfaces.

Of the latter two, XB 161 was most widely used, since its price is relatively low. In addition, the XB 161 paint is almost universal in the matter of temperature conditions - you can work with it in the temperature range from -20 to +40 degrees.

Characteristics XB 161

Here are the main technical characteristics of perchlorovinyl facade paint ХВ 161:

- Drying time (ambient temperature is 20 degrees above zero) - no more than a day;

- The consumption of paint per unit area is about 270 g with an average layer thickness of about 25 microns;

- Viscosity - 30-45 s. This value of this indicator allows you to use a spray gun, without adding solvents or other diluents;

- The relative amount of non-volatile substances is not more than 47%;

- After solidification, the layer has bending elasticity - a maximum of 5 mm;

I must say that the other two species have similar indicators, but still different from the data.

Advantages and disadvantages

Like any other material, this enamel has its own positive and negative qualities.

The advantages include the following properties:

- Very high adhesion. This allows the paint to be absorbed deep into the structure of the substrate, which creates a barrier against moisture. In addition, the paint itself is able to maintain its integrity for a very long time;

Advice!

To further increase adhesion, before using this material, the surface is coated with special perchlorovinyl primer.

- The presence of several species allows the use of similar enamels on all types of surfaces;

- Possibility to stain even at low temperatures (which is more relevant to XB 161);

- Preservation of saturated and deep color for at least 5 years. Such paints begin to “fade” only after 3 years, but even after 5 years they remain quite bright, in comparison with ordinary acrylic enamels.

Negative properties include the following:

- Inability to work in extreme heat or rain. In no case can such paints be mixed with water, and a large amount of ultraviolet light will cause the paint to crack before it has completely dried;

- Fairly low elasticity, which requires evenness from the base. Otherwise, cracks will appear.

Advice!

So that the paint dries longer, which is especially important in the case of high ambient temperatures, a soap solution can be added to it.

Indeed, adding a little soapy solution, you can ensure that the paint will dry for a longer period, which means that it does not crack even at very high temperatures.

It must be said that GOST for perchlorovinyl facade paints does not imply the presence of such a solution, therefore, to say how much it can not be added precisely - the more the solution, the longer the paint will dry.

By the way, GOST for perchlorovinyl paint (only for ХВ 161) has a digital designation 25129-82.

Application features

Instructions for the use of perchlorovinyl paint are slightly different from the instructions for use, for example, with acrylic enamel.

All DIY work must be carried out in compliance with the following rules:

- Before use, the container with the material must be left at room temperature for at least 8 hours, which will reduce the viscosity;

- The surface to be treated must be cleaned, washed and leveled (we spoke about irregularities a little higher);

- As already mentioned, before applying it is recommended to coat the treated surface with varnish, for example, XB-148, and over (for leveling), XB-0018;

- Throughout the work, the paint should be thoroughly mixed;

- If necessary, it can be diluted. As diluents, it is recommended to use solvent or xylene, but in an amount not exceeding 1/10 of the total volume;

- Apply in two layers. This is due to the fact that the first layer is almost completely absorbed into the base material. The interval between applications should be at least 24 hours;

Conclusion

From all of the above, one simple conclusion can be drawn: this type of enamel and paint fully justifies its popularity, despite the relatively recent appearance in the markets. Those disadvantages that are associated only with the features of the application are more than compensated by durability and low cost.

You can learn more about this question from the video in this article.

Finishing facades by painting is a fairly common method, it is used even more often than other finishing materials. This is not surprising, because painting is almost the oldest way to give the building an aesthetic appearance. A huge variety of varieties and types of paints can confuse even an understanding person when choosing. It is worth knowing that facade paints are very different and not only in color and consistency, but in terms of their technical characteristics, durability and quality. Perchlorovinyl paint is one of the types of facade paint, which has a lot of advantages and deserves special attention.

Features and properties of facade paints

In order to be able to compare and evaluate the quality of the material, you need to understand the features and basic properties of paints in general, what a number of advantages they should have, and what makes them not high quality. In the case of perchlorovinyl paint, the following should be said:

- its components create high protection against all types of atmospheric effects, from ultraviolet radiation, rain, frost and snow. The paint is very well in contact with the surface and deeply penetrates inside, which creates a reliable layer of protection against the penetration of moisture and maintains the finish much longer;

Perchlorovinyl paint feels equally good on wood, concrete, plaster and brick. This greatly expands its capabilities and, unlike acrylic paintmakes it almost universal;

An unambiguous plus is the frost resistance of perchlorovinyl paint, it does not thicken even at minus 15-20 ° C and can be used in winter painting, which puts it higher than other facade paints. The only condition is that when painting in winter, you can not add plain water;

Regardless of the shade of perchlorovinyl paint, the color will be saturated and remain so for 2-3 years, regardless of weather conditions.

It is worth remembering that such a paint can not be applied to the surface if it rains or snows, the facade should be dry, without spots of moisture. Also, direct exposure to the sun and intense heat are favorable for painting; it sets and dries very quickly, therefore spots and cracks may appear. On a hot day, you can paint the walls gradually and paint the side of the house where the sun does not fall. Experts recommend adding a little liquid soap to the perchlorovinyl paint in the heat, which will increase the drying time.

However, these disadvantages are present in almost all facade paints, so you should pay attention to the positive aspects.

Surface preparation

Before painting the walls of the house you need to alert, scale preparatory phase depends on what material the walls are made of. For example, a wooden house must be treated with antiseptic agents, then apply a primer layer and create a good hitch for the paint.

If the house is made of concrete slabs and they already had a coating, then the paint layer must be removed, given the large amount of work, it is best to use equipment such as sandblasting, or clean with a hand tool. Then the surface is washed off with water and covered with a primer. Removing the old coating is a prerequisite, otherwise the adhesion will be much lower, which will affect the quality of work and operating time.

If the house was insulated, then in addition to the standard layer of plaster, it is necessary to make reinforcement with a mesh so that the surface does not deform.

Paint application

Despite the fact that the painting process is well known to everyone, you need to follow some rules for staining and using directly perchlorovinyl paint.

In no case should paint be mixed with other types of paint, as is sometimes done to obtain original shades. Perchlorovinyl paint has its own wide range of colors, from which you can choose the desired color. It is worth knowing that the paint contains xylene and solvent, which are harmful to the skin and especially the mucous membrane, so you need to paint with gloves and a protective mask. Perchlorovinyl paint is not allowed to be used indoors. The process of applying paint can be done manually, using a roller and brushes, or with a spray gun, which is much more convenient and faster.

Regardless of which painting method you choose, in all cases with staining, you need to apply the paint starting from the top and leading down, rolling or covering the stains from above. The roller should be driven by direct vertical or horizontal movements, you cannot write circles or roll the paint diagonally in different directions, otherwise the stripes will be visible after drying.

To get a saturated color and a dense coat of paint, you need to apply two layers. In this case, you need to correctly calculate the amount of paint and not spend extra on the first layer. The first layer should cover the entire surface with a uniform thin film, you should not seek perfect shelter and roll one place several times. The second layer is applied after the first has dried and covers all the flaws of the first, plus it is no longer absorbed into the wall, so saturation and brightness will appear with the second layer.

Do not stop at half the work, it is recommended to paint over the selected area in one go, otherwise the stripes between the layers applied with a break may be noticeable. With the right approach, the paint consumption for a two-layer coating is not large.

For one layer per square meter, 150-230 grams are expended; accordingly, about 400 grams will be spent on two layers. When choosing, you need to pay attention to GOST, since perchlorovinyl paint has the designation 25129-82, and if you meet a different marking, it may well turn out to be a fake. High-quality perchlorovinyl paint has a guaranteed shelf life of 10 years, while it should not be exposed to the sun.