Decorative bark beetle. Finishing the facade of the house with decorative bark beetle plaster - prices

Monotony in the design of facades and interior decoration houses left in the past. A wide range of products intended for decorative finishes walls. Plaster with the eccentric name "Bark beetle", intended for exterior and interior decorative work, occupies a worthy place among the assortment. What are its features and forms of application, we will get acquainted in detail. The proposed video lessons will consolidate the information received and help you independently master the technology of applying the finishing material.

Structure and characteristic properties of decorative plaster

Decorative plaster got its name due to the pattern, which is formed on the surface of the walls as a result of its application. It successfully imitates the traces of the activity of the bark beetle that remain on wood material. Depressions of various shapes and lengths are formed on the surface of the walls due to the content of fine granules of mineral chips or marble in the composite plaster. Their size varies from 0.1 to 3.5 mm. Depending on the selected fraction, the thickness of the decorative layer of the applied bark beetle plaster and its consumption change. It also affects the texture of the surface of the walls.

What properties of bark beetle plaster have provided it with a leading position among other materials intended for decorative decoration, we will consider in detail:

- The content of polymer components and mineral fillers in the composition instead of sand provides the bark beetle plaster with ease, therefore, when decorating the walls, additional stress on individual elements of the building can be avoided.

- The absence of toxic substances in the composition guarantees environmental safety during operation.

- The bark beetle plaster retains its properties at temperature fluctuations from -55 o C to +60 o C. At the same time, it is not afraid of atmospheric precipitation and exposure to sunlight.

- The decorative bark beetle in the interior of the house is not affected by fungus. Proper finish protection provides stability when in contact with a damp sponge or gel-based chemicals used to clean the surface of walls.

- She is not afraid of damage as a result of mechanical shock of moderate severity.

- Hydrophobic and vapor-permeable properties, as well as resistance to the action of an open flame are the next advantages to the piggy bank of the advantages of bark beetle plaster.

The main color in which the decorative plaster is produced is white. If you want to diversify the interior of the room or the facade of the house, the bark beetle decoration easily changes color in two ways. In the first case, the total weight of the plaster is tinted before applying the decorative layer, or the paint is applied after the walls have been decorated with a bark beetle. Possible trim variations will be discussed later. The photo below demonstrates the interesting texture of surfaces after decoration decoration material.

Features of various kinds

Depending on the basis, the Bark beetle plaster is divided into 3 types, each of which differs in the form of release, cost and period of operation. Let's take a closer look at the properties of each product line:

- Decorative material for walls with a mineral base is available in powder form and requires self-mixing before application. Its strength only increases over time. Low elasticity of the gypsum base can cause cracks. Of all types of bark beetle, this is the cheapest plaster, due to its resistance to mechanical stress, it is actively used for exterior decorative decoration of houses.

- Acrylic-based plaster is available ready to use and does not require additional steps to mix the components. Acrylic-based bark beetle is very flexible, it opens up wide prospects for interior design and allows you to create a unique pattern on the wall. Decorative acrylic plaster has the longest period of operation, prevents the appearance of mold, it easily removes dirt. The combination of all properties determines the high cost of such a "bark beetle".

- Silicone plaster is a kind of alloy of decorative materials based on acrylic and gypsum. She successfully combines the best qualities of both types. Its main purpose is the decoration of facades.

The procedure for preparing a decorative plaster mortar and application technology can be found in the following video tutorial:

Application methods for exterior decoration

Due to its properties, bark beetle plaster is actively used for decorative decoration of building facades. Concrete and brick surfaces, as well as stone, are suitable as a basis for application. This can be a full-fledged processing of walls or the design of individual elements. Combined surfaces are distinguished by originality when small areas on a solid wall are highlighted in a different color or method of applying plaster.

The procedure for the formation of decorative bark beetle during outdoor work will be considered in detail:

- In some cases, before starting work, the building intended for decoration needs to be insulated. Foam sheets are suitable for these purposes, a material thickness of 5 cm will be sufficient.

- The insulation panels are fixed to the walls of the house using TM Cerezit glue. After it dries, the surface is additionally strengthened with fasteners “umbrella”.

- In order to prevent cracking of decorative plaster in the course of further operation, reinforcing mesh is installed on the walls. Its second function is the formation of a flat surface.

- Previously, external walls need to be treated with ordinary plaster.

- Priming the surface will help increase the adhesion of the two solutions.

- After the composition dries up, they switch to a decorative bark beetle finish.

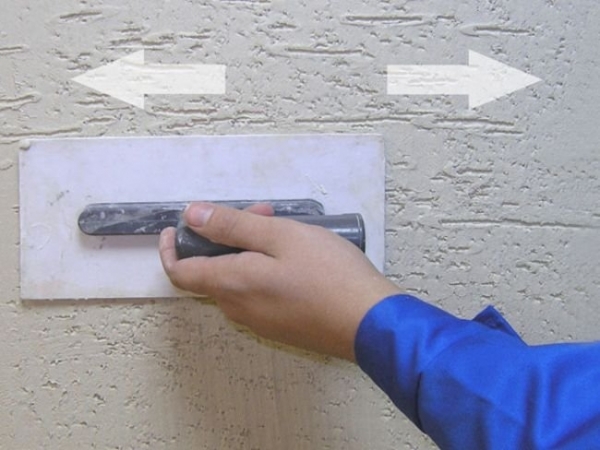

First, the solution lies in an even layer, the thickness of which is determined by the size of the granule fraction. Depending on the desired result, the plaster is applied in different ways. When the decorative finish ceases to adhere to the tool, they proceed to the formation of the pattern. Movements can be horizontal or vertical, observing parallel lines. If you want to create some kind of abstraction, the movements are circular or chaotic. To form the picture using a plastic grater. Due to the slip of solid inclusions on it, different size furrows form on the decorative plaster.

Advice! The depth and width of the lines can be adjusted by changing the pressure of the tool.

After drying decorative material, the bark beetle can be given any shade you like. The final result of the work can be seen in the following photo:

If you want to emphasize the corners of the house or decorate the building with decorative elements, use 10 cm thick foam. Corners and other additional details are painted in colors that are darker in relation to the main background. What nuances should be taken into account when organizing outdoor work on applying bark beetle plaster, you will learn in the following video tutorial:

Interior design

Plaster bark beetle for decorative decoration ТМ Ceresit avoids the same type not only when processing external walls, but also when decorating the interior inside the house.

Note! If for facades a material with large granules is chosen, then it is preferable to process the internal walls with plaster with finer granularity.

Ceresit brand offers “Bark beetle” in two shades - white and gray. Its further application suggests the possibility of staining in the desired color. Next, we will review what is the technology of applying plaster indoors, and how to use it to give the interior a unique design:

- The wall before applying decorative finishing to the bark beetle needs preparation. Large cracks and chips are fixed with a solution of ordinary plaster, if necessary, they are pre-embroidered with a grinder. The use of sickles or plaster mesh will prevent the destruction of unstable sections of the wall.

- The old decorative coating must be removed, the polymer or oil surfaces are cleaned mechanically or using a solvent.

- Further, the wall is treated with a primer, for these purposes, the composition of Ceresit ST 16 is suitable. Primed with a brush, the roller is not recommended.

- After drying, the walls proceed to mixing the solution. The temperature of the water should be kept within 15-20 ° C, a dry bark beetle mixture is gradually poured into it.

- For high-quality mixing, a drill equipped with a special nozzle or mixer is used. It is optimal to select a mode of 400-800 rpm. The desire to shorten the process by increasing the speed of rotation will lead to aeration of the stucco mortar (i.e. it will fill with air bubbles), and this will negatively affect the quality of the decorative finish.

- After mixing, the plaster solution is allowed to stand for 5 minutes for a complete relationship of all components, after which it is re-mixed and ready for use.

Important ! It is necessary to induce such a volume that can be used over the next hour. In the future, it will begin to lose its properties and the addition of water will not save the situation.

- The optimum temperature for applying decorative finishes in the room should be more than 5 ° C and not exceed 30 ° C.

- A stainless steel grater, with which a decorative mortar of bark beetle is distributed, is held at an angle of 60 ° to the wall. This allows you to form a layer whose thickness does not exceed the size of the solid granules.

- If necessary, interrupt the process, to prevent drying, the edge of the plaster is covered with masking tape, which is removed when the process is resumed.

- After half an hour after application, you can proceed to grind.

To create a highlight in the interior of the room will allow various techniques for finishing decorative bark beetle plaster. Specialists offer the following techniques in the design of walls:

Warning ! Materials for the final decorative finish are selected of the same brand as the bark beetle plaster applied to the wall surface.

Updated:

2016-08-19

2016-08-19

Today, increasingly, stucco buildings and private homes. This is due to the obvious advantages of the material, and the price is often affordable. Therefore, for many, the choice is obvious. Nevertheless, there are various stucco mixtures, each of which has its own advantages, features and disadvantages. Today we’ll talk about decorating the facade with a bark beetle, that is, with special plaster, which has the unusual name of a bark beetle. High quality finish The facade of the house bark beetle provides a wide range of benefits, which explains its popularity.

- The basis for creating the mixture is cement and marble chips. Moreover, the size of this very crumb directly affects the species of bark beetle. Plus, this affects the layer that needs to be laid on the wall surface. So, if the grains are small, then a thin layer is required, and you will create a uniform application. If the fractions are large, then the material consumption will be greater.

- Color. Initially, the material can not boast a wide variety of colors - white and gray. However, due to wet tinting, you can significantly change the appearance of the finish.

- The material got its name due to the texture of the walls after they have completely dried. They are covered with grooves that look like holes left by a bark beetle on tree trunks. As a result, the decoration of the facade with a bark beetle has an incredible and original appearance. Make sure of this yourself by looking at the finish of the facade with the bark beetle photo. For a bark beetle, a facade of any complexity is a doable task. Another question is whether you will perform the work or entrust the facade of the house to specialists.

Benefits

If you are interested in this stucco photo you can clearly verify the rationality of the choice. Before us is a wonderful material, which can have a different color, attractive price and a pleasant result after wall decoration. But let's dwell on its strengths in more detail.

- The material is natural and environmentally friendly, because it does not contain hazardous components and additives.

- The surface covered with bark beetle plaster is durable, not afraid of atmospheric phenomena, constant exposure to water and mechanical damage.

- Plaster bark beetle is not afraid of contact with acids, alkalis, industrial gases, and therefore it is often used in industrial facilities.

- Easy to apply, drying takes a minimum of time.

- Unusual appearance, which is clearly seen in the photo. In fact, the bark beetle is not like any other alternative plaster.

- Attractive price. And very much so. Even with additional insulation, waterproofing, the work will cost much less than installing the same curtain wall.

disadvantages

Unfortunately, but the bark beetle also has its negative sides. Although the flaws are not so serious, you must definitely know about them:

- It is applied only by a person with experience, professional skills and knowledge. It is extremely difficult to independently work with the material, the result can turn out unpredictable;

- It is difficult even for a professional to mask a chip or damage to a layer as a result of mechanical stress, plus this area will still be noticeable;

- Seasonality The bark beetle can be laid on the wall in low humidity, in the absence of precipitation and not under direct sunlight. Air temperature should be above 10 degrees, but not more than 50 degrees Celsius.

Kinds

Modern stucco called bark beetle can be of two types:

Modern stucco called bark beetle can be of two types:

- Acrylic

- Gypsum

There is a difference between them, and quite substantial. If you look at the photo, it will become obvious - acrylic mixtures look much nicer and richer. Nevertheless, the technology of their application is complex, has many features and nuances. Therefore, it is worthwhile to entrust the finish to specialists immediately.

Also, the acrylic look is sold on the building materials market in the form of finished thick mass. All you have to do is add the color you like and mix the solution in the bucket in which it is sold. Although manually achieving the perfect consistency is quite problematic.

But the gypsum mixture is sold dry, its price is much lower, the color can also be different due to the paint. The plus is that applying it on the surface is much easier. Someone will say about the need to independently prepare a solution, but this is hardly worth mentioning as a disadvantage. An ordinary drill, a mixer type nozzle - and you're done. Of course, one should strictly adhere to the manufacturer's recommendations regarding the proportions of dry mix and water.

Application Features

As we have already noted, wall decoration with bark beetle stucco is best left to professionals. Nevertheless, this does not prevent you from familiarizing yourself with some of the nuances of work.

- Water. Without a properly prepared mixture, finishing will be extremely difficult. Here it is enough to follow the instructions that the manufacturer applies to his dry mixes. No amateur performances. Kneading is carried out in several stages. After the last plaster should be slightly infused, swell and acquire the necessary consistency.

- Primer. In addition to preparing the walls, which is an extremely important issue, they still need to be primed. Use quartz sand primers.

- Season. Finish preferably in the spring or in the fall. This should not be done during periods of frost or extreme heat, as this will negatively affect the quality of the walls.

- Sequence. Having taken up the decoration of one wall, do not switch to another, finish it first. Otherwise, the joints of the layers will be very noticeable, and even intense painting will not allow to hide these traces. The same angle on both sides does not need to be done. Proceed alternately.

- Color. To obtain the desired color, color is added to the acrylic blends. Dry solutions are not tinted, but they acquire the desired shade by painting the walls with facade paints after applying layers of plaster. Painting is pretty simple. To do this, you need a simple roller, or a modern spray gun. Focus on the photo of the houses you like, or realize your fantasies about decorating walls, if you do not want the usual monophonic solutions. This stage, by the way, can be completed by do it yourself, and paying extra to the masters is not necessary.

Well, bark beetle is an excellent finishing material, which is widely used today in residential and industrial construction. Its price attracts the attention of a huge number of those who plan to upgrade their facade. Try this material yourself, and take a photo before and after applying the bark beetle. The difference will pleasantly surprise you.

The exterior walls of the building can be finished in many ways. Choosing the most suitable is a matter of awareness, skills and financial capabilities.

Using facade plaster - tribute to traditions, the opportunity to get a high-quality coating that protects the wall material, contributing to the removal of steam with water-repellent properties of the surface and, most importantly, amenable to partial repair.

The appeared spot of damaged coating can be easily repaired as if there was no flaw, which is much more difficult to do when finishing, for example. In addition, the plaster can be repainted, changing the appearance of the house without carrying out any complex work.

The choice of facade plasters, let us consider in more detail one of them - Bark beetle plaster.

Facade plaster Bark beetle is a textured coating having a surface with a mass of grooves, pits or strips imitating traces of insect pests in a tree massif. The absence of a flat plane allows you to hide small surface defects, to mask possible irregularities or other defects of the walls.

Moreover, the aesthetic component of such a coating is very high, the surface looks very solid and attractive. The composition of the mixture to obtain a bark beetle plaster can be based gypsum or acrylic basedmoreover, the gypsum mixture is sold in the form of a dry powder, which is diluted with water before application, and the acrylic compositions are sold ready to use.

Specific grain gives the appearance of the coating - small pebbles (marble chips), which create grooves under the grater, giving the surface a recognizable look.

The grain size in the composition may be different - from 0.8 to 3.5 mm, which changes the surface topography, making the grooves larger or smaller.

Below is a photo of the facade of a private house covered with bark beetle plaster:

Specifications

There are many manufacturers that make a mixture of bark beetles. Each of them seeks to add to its composition some ingredients that enhance one or another parameter or effect. Therefore common technical specifications does not exist, however, some qualities common to all types of mixtures can be distinguished.

These include:

- The coating is quite light, does not create an unnecessary load on the walls.

- Operating temperature range from -55 to +60 degrees, when heated, does not emit harmful volatile substances, does not fade, is fire resistant.

- The surface is durable, can withstand not too strong shocks, can be cleaned with a brush or vacuum cleaner.

- Water wash resistant, resistant to precipitation, chemical compounds, does not contribute to the formation of mold.

- The base color of the composition is white, the composition is not tinted, but after drying it can be painted in any desired color.

- Environmentally friendly completely safe, does not contain any harmful impurities.

- The average consumption with a layer thickness of about 3 mm is 3.5-4 kg / sq. m

- The prepared solution is suitable for application within 2-3 hours.

- The drying time of the coating is 2-3 days, a set of full strength is achieved in a month.

- Frost resistance - 50 cycles.

Usually a dry mixture (the most common and used type) is sold in 25 kg bags, the contents of one bag covers 7-8 sq.m. surface.

It can be applied to the following types of substrates:

- Plaster.

- Drywall.

- Brick.

- Concrete.

The texture and surface pattern depend on the size of the grain, the skills of the plasterer and the direction of the grooves.

Other types of textures for facade plaster

There are other types of facade plaster, which can have a basic composition of different elements, for example:

- . They are considered the most durable and economical, in addition, strength only increases with time. The basis is cement with various additives, the mixture is not tinted and must be painted.

- . The elastic surface tolerates fine movements and shrinkage of the building. It has good water-repellent qualities and high vapor permeability, which allows the coating to easily tolerate temperature fluctuations.

- . Expensive and very high quality coatings. They are distinguished by their universality, they protect against all harmful effects - moisture, sunlight, temperature extremes, etc. The composition is easily tinted, having a wide range of colors, which increases its working qualities. Due to the high price, the use of such plasters is limited, but their quality is very high.

- . Plastic, vapor-permeable mixtures, are easy to apply and do not retain water. They are successful in busy streets, where a high dust content in the air is possible, as they are immune to pollution.

There are other materials for outdoor work, as manufacturers are constantly in search of new, more attractive and high-quality additives, compositions and bases for coatings.

Types of decorative plasters

How to mix the decorative mixture

The quality and strength of the resulting coating depends on the correct preparation of the working mixture. Meanwhile, the procedure is simple.

Required:

- Container for mixing the composition (e.g. bucket)

- Mixer for kneading. An electric drill with an adjustable speed is suitable.

- Dry mix.

- Water.

On the packaging there is an instruction in which the proportion of the dilution of the mixture is indicated.

NOTE!

The amount of water and dry mix must exactly match the proportions specified in the instructions, otherwise the quality of the coating will be poor.

The mixture is thoroughly mixed with a mixer and left to swell. After a few minutes, stir it again (you can repeat the operation three times). This will help break the lumps and contribute to high-quality "maturation" of the composition. The finished solution has the consistency of thick sour cream or mashed potatoes.

Mixture consumption Bark beetle

The peculiarity of the Bark beetle mixture is that it is applied immediately to the entire plane - the entire wall at a time.

This means that you need to prepare the right amount of mixture, since its availability is limited, and interrupted during work to prepare a fresh portion of the mixture - means setting the edge of the applied composition.

The junction of the two layers will be noticeable, all the work will be if not spoiled, then done poorly.

Stucco Bark beetle is a finishing coating that is applied in a thin layer to the prepared surface.

The layer thickness should approximately correspond to the grain size, otherwise with a thicker application, grooves will not turn out, making the surface recognizable and attractive.

The whole point of applying such a composition will be lost. Therefore, the consumption of the finished mixture is quite economical, per 1 sq.m. surface takes about 3 kg of the composition. Depending on the thickness of the coating or grain size, the flow rate may vary in one direction or another, but the average value is approximately the same as indicated.

CAUTION!

Some sources indicate a layer thickness of Bark beetle plaster equal to 1 cm or more. Most likely, in this case, along with the finish, the thickness of the preparatory layer is taken into account. Bark beetle itself is not applied in such a thick layer.

Surface preparation for application

For high-quality application of decorative coatings, prepare the surface. It must be cleaned of dirt and dust, old wallpaper or paint, peeled off peeled plaster, etc. The prepared wall should have a clean and dry surface without shedding, deep dents, cracks and other flaws that cannot be hidden under a thin layer of topcoat.

- Detected cracks or dents should be treated with a spatula.Remove peeled or chipped pieces so that the edges represent a failure of the solid monolith without signs of peeling.

- Then all the flaws discovered problem areas are filled with mortar with a spatula, primed or putty - depending on the condition of the surface.

- If the quality of the wall surface is unsatisfactory, you should plaster it with a sand-cement mixture - create a preparatory leveling layer. To do this, you can install lighthouses on the wall - special strips that serve as a support for the rule by which the surface plane is displayed. Usually two beacons are installed at the edges, their position is adjustable in level.

- Then a cord is stretched between them, along which intermediate beacons are installed. The distance between them should be 10-15 cm less than the length of the rule. After a few hours, the surface is pre-rubbed, the next day is a full grout.

Surface preparation

Surface priming

The plaster layer should be well dried, if work is carried out on hot days, it is recommended to water the plastered surface daily with water from a hose to prevent cracking. The cracks that have appeared are wetted, then they are again overwritten.

DIY application and reinforcement technology

When applying a decorative coating to or other external insulation is used intermediate coating technology. It includes the preliminary application of a layer of glue for the tile on the surface of the insulation, installation of the mounting mesh -, the alignment of the preparatory layer with another adhesive layer.

After this, the primer of the preparatory layer is made. When reinforcing, the mesh is not only installed on top of the adhesive layer, it is pressed into it to achieve full and durable contact. The second layer should completely hide it inside.

Reinforcement

Grid fitting

The surface of the preparation should be smooth and accurate, since the final appearance of the wall largely depends on it. For this, the adhesive layer is best applied with a notched trowel., it evenly distributes glue on a surface, leaving the calibrated strips which subsequently are crushed by a grid and covered with the second layer of glue.

Topcoat application

For application, use a metal spatula. Creating a surface texture is done with a grater or a half. An important element of the work is to gain the skill of applying a layer of the desired thickness.

For application, use a metal spatula. Creating a surface texture is done with a grater or a half. An important element of the work is to gain the skill of applying a layer of the desired thickness.

If pebbles are rolling under the grater during the movement of the grater, then the layer is correct and the surface will have a specific pattern - stripes and grooves resembling insect-eaten wood.

The direction of movement of the grater is an important point on which the orientation of the grooves and surface texture lines depends. In which direction the grater moves, the grooves will be located.

If there is no need to obtain a surface with a certain direction of the pattern, then the movements of the grater should be circular, more or less sweeping - depending on the size of the grain in the mixture.

The application of the first layer of plaster and the creation of the final coating are operations that are 10-15 minutes behind in time from each other. That is, first a layer of plaster is laid on the surface and is “stretched” to the required thickness.

Then, after 10-15 minutes, when the composition begins to set, the layer is smoothed with a grater to obtain a characteristic pattern. Immediately upon application, it is difficult to obtain the desired surface.In addition, the composition is not suitable for use for long, it is important to manage to do everything.

Layer application

Create horizontal terrain

Create vertical relief

Painting plastered surface

Wall bark beetle mix color - white. The composition is not always subject, therefore, after the plaster dries. To give the surface the desired color can be used facade paints certain colors, the choice of which depends entirely on the tastes of the owner.

At the same time, one can note a successful option, often used with this type of finish - double painting. Usually it is done like this: the surface is pre-painted with special emphasis on the depressions. A second coat of paint of a different color (usually lighter) is applied so that dents or the bottom of the grooves are not affected.

Plaster painting

For this purpose, you can use a paint roller with a flat surface. The result is a surface with an emphasized expressive texture, very aesthetically pleasing, and also covered with a double layer of paint.

Decorative plaster Bark beetle - effective and aesthetic coating for outdoor work, easy to apply and attractive in terms of quality and composition. The possibility of independent decoration, ease of operation, subject to a few simple rules make this coating common and preferred from an aesthetic point of view.

Workshop on applying bark beetle plaster

High-quality video instruction for decorating the facade of the Bark beetle:

In contact with

If you are tired brick walls and plastic lining, there is a great way not only to update the facades of houses, but also other rooms in them, using decorative textured bark beetle plaster.

It is an environmentally friendly material, beautiful in appearance and can be used in rooms for various purposes.

For reference: the bark beetle plaster got its name because of its similarity to the bark beetle that has eaten wood, which gnaws small narrow passages in it.

The plaster dries quickly and is ready for painting in just 6 hours. After a day, she will no longer be afraid of rain, frost and other atmospheric phenomena. Its price is not cheap, but it is worth it.

Prepare the tools:

- fur roller;

- electric drill and nozzle mixer;

- spatula or trowel;

- one and a half;

- polyurethane grater.

Application technology "Rain"

In this example, the decoration of the walls by the bark beetle in the option of vertical parallel stripes or “Rain” will be considered. This effect is obtained due to the content of granite pebbles with a diameter of 2-3 mm in the mixture.

Tip: when using bark beetle plaster in the Rain technology, you cannot apply horizontal layers at different times, it will be very noticeable on the finished surface.

In the photo - textured finish of the balcony with a bark beetle

Preliminary stage

Below is a detailed instruction on the process, which, we hope, even a beginner plasterer will cope with:

Therefore, the surface of the wall, for example, from the foam block must be cleaned from the remnants of the suture solution, ensuring that it becomes smooth, even and does not have differences.

It will be better to stick a plaster reinforcing mesh on the insulation.

- Strip the seams with the middle grain of sandpaper. Put a respirator on your face, and protect your eyes with construction glasses, as the work will be dusty enough. After stripping, no mortar or other protruding elements should remain on the wall.

- Prime the surface with a roller. Try not to skip space on the wall. Typically, a deep penetration primer is applied 30 minutes before the bark beetle is applied, this will help it cling better to the facade surface. (See also article.)

Tip: the primer should be either white or in tone with the bark beetle, so that a different color does not appear through its thin layer.

It is advisable to use primers and putties from the same manufacturer in order to guarantee the compatibility of materials, as well as the quality and long service life.

- Prepare a solution, for which it is more profitable to purchase a dry mixture in the form of a powder, and then dilute it with water, according to the instructions on the package. Mix with a drill with a mixer tip. After the first stirring, leave the solution for 10 minutes. If everything was done correctly, you will get a thick creamy plaster.

- Take a plastic or metal grater and begin to pre-apply the mortar on the prepared surface of the facade. In addition, in your second hand you should have an ordinary spatula, which is convenient to impose the mixture from the container on the grater, and then collect them from its edges in the center.

This stage involves only applying an even layer of plaster, while its thickness depends on the diameter of the individual pebbles in the mixture. A properly prepared mixture does not drain down, sticking well to the wall.

Tip: Use the perforated metal corners to frame the corners of the building.

Attach them to the wall and apply a layer of plaster on them.

Main process

Complete the preliminary step by cleaning all the tools from the mixture. Also, for the next stage, prepare a polyurethane grater, having washed its working side well. It will be she who will play the main role in the formation of the drawing on the facade.

- Take a grater and begin to move it along the facade in parallel vertical stripes, creating a textured pattern “Rain”. Do not forcefully press the wall, or move the tool horizontally or in a circle. When moving in a dried mixture, the grooves will create granite chips in its composition.

After complete drying, the facade can be painted and protected with special compositions at its discretion.

- Apply the plaster in a smooth motion, holding the grater almost vertically. If you allow an acute angle to the wall, then horizontal lines will remain on the plaster. You can’t remove them, since all the binding material remained on the grater and the stones were on the wall, so the layer should be removed.

- When a large layer was applied to the wall, it will have to be reduced by moving the grater up and down, collecting it until you reach the proper thickness. Therefore, you do not need to be afraid of this.

- If you need to cover decorative plaster a large section of the wall, any smoke breaks, toilets and telephone conversations should be set aside. Do not trust that it will be possible to make a cut-off with masking tape of one vertical part from another, anyway the strip will be visible. For beautiful facade it is unacceptable.

- Do not work with textured plaster in strong winds, if there is little experience, or under scorching sunlight.

- When applying bark beetle to drywall, it must be pre-treated with Sheetrock putty or its equivalent.

- The “lamb” pattern is obtained when grouting the plaster in a circular motion.

Conclusion

In fact, plasterers today received material that can seriously compete with other facade and decorative finishes. Applying it does not cause difficulties, it is only necessary to take into account the nuances of specialists.

If this is your first time deciding to try yourself as a plasterer, practice in small areas and keep your tools clean. In the video presented in this article, you will find additional information on this topic.

A wonderful texture on the surface of the plastered wall appears after applying a composition with the funny name Bark beetle. This is the most popular decorative plaster today, which is easy to lay, looks unusual and lasts a really long time. Although it looks like a tree pretty badly eaten by bugs.

Despite the variety of bark beetle mixtures, they all have excellent performance characteristics:

- good temperature tolerance in the range of -55 - + 60 ° С;

- water tightness;

- persistent shades in polymer compositions dyed in bulk;

- resistance to the effects of certain chemical "aggressors" - acids and alkalis;

- high mechanical strength, as well as resistance to abrasion.

All this makes the plaster with the texture of bark beetle an ideal option for decorative decoration of facades. But there is one drawback - in case of restoration of the damaged coating, the “patch” will be clearly visible, so after repair work you will have to repaint the entire wall with your own hands.

Types of textured mixtures

1. Acrylic plaster Bark beetle is a ready-made polymer solution, which is easy to work even with the most inexperienced master. The only negative is the lack of air tightness, therefore, it is undesirable to use acrylic compositions in living rooms or on actively "breathing" bases.

Acrylic solutions have a relatively low consumption when compared with heavier mineral ones. And elasticity ensures no cracks even when shrinking bearing walls and thermal expansion of materials. The main thing is not to apply acrylic bark beetle on the still not dried base plaster, so that as the lower layer hardens, no bubbles and delamination appear on the coating.

2. Polymer-cement - vapor permeable, but not very plastic. At the same time, it has high strength, albeit insufficient durability (about 10 years). So that cracks do not appear on the surface of the decorative finish, it will be possible to apply it only after the house has shrunk.

The cost of a bag of dry textured mixture seems quite acceptable, but if you take into account the cost per square meter, the repair price can increase unpleasantly. In order not to spend extra money, it is better to perform a preliminary alignment of the walls with an ordinary cement-sand composition. In time it will come out longer, but it will reduce the cost of decoration.

The preparation of the solution is described in detail on each package. But for most dry mixes, recommendations from different manufacturers do not differ:

- Pour the contents of a bag with decorative dry plaster into a container of water at room temperature.

- Stir thoroughly until the lumps disappear.

- Close the container and leave the solution for 10-15 minutes, then mix again and proceed with application.

3. Silicate plaster is excellent for outdoor use. Such a coating on the facade not only tolerates any weather conditions for 20 years, but also has antistatic properties. As a result, dust does not accumulate on the wall surface, and it is easily removed from textured grooves during rain or simply washed off with water and a brush, minimizing the maintenance of the facade.

The application technology of Silicate bark beetle requires the use of special primers for better adhesion to the base.

4. Silicone plaster is the most expensive variety, which is suitable for decorating the interior of a apartment as well as for standard outdoor work on the building’s facade. It has the best performance characteristics similar to those of a silicate coating and can also last for decades. It reconciles with its high cost.

5. Gypsum - a dry mixture of bark beetles, which is much cheaper than ready-made compounds. You can read about the features of decorative plaster mixes. It is not difficult to do it yourself, but for cooking you will need a drill with a mixer nozzle. Decorative plaster should be slightly thicker than the usual leveling, and in consistency resemble mashed potatoes.

The solution in the process needs to be mixed from time to time so that the filler grains are evenly distributed throughout the mass. But to dilute with water already ready for application, the mass can not.

Plaster for walls on a gypsum binder can only be used for internal work. For the decoration of the facade it is better to buy an acrylic or silicate mixture.

Decorative finish

The appearance of a recognizable pattern of bark beetle on the surface of the plaster provides small marble or quartz chips with a particle size of 0.1-4 mm. Not only the texture of the coating, but also the consumption of plaster per 1 m 2 depends on its size. The smaller the granularity of the aggregate, the easier the finish layer.

Like most decorative compositions, Bark beetle should be applied to a previously prepared and leveled surface. Although the expressive texture will help partially hide the slight flaws in the base. But to reduce consumption, you should first apply a layer of ordinary plaster. It is important that it is strong enough and able to hold on to itself, albeit insignificant, but still overweight coating.

Actually the consumption of Bark beetle will be easy to determine. The wall area is measured with an ordinary tape measure, and the layer thickness will be approximately equal to the size of the mineral filler indicated on the package. It remains only to multiply the manufacturer's data on the consumption of plaster per square meter and the measured area to get the exact amount of the mixture for the entire repair.

Small differences in the calculations will concern only dry gypsum decorative compositions, since their consumption will depend on the volume of water used to prepare the solution. In order not to be mistaken, you can add another 5-10% “on your own” to the data on the package and buy a little more mixture in reserve.

Application technology

When the surface is prepared, it will be necessary to additionally strengthen the corners with a special aluminum profile. Then you can begin to work:

1. Apply a thin layer of plaster with a texture of Bark beetle, with a thickness not exceeding the maximum grain size. In this case, the tool must be held at an angle of 60 ° to the wall.

2. After half an hour, when the decorative plaster hardens sufficiently so as not to stick to the tool, it must be smoothed out with a flat plastic grater.

3. The movement of the grater, as well as the number of passes will determine the nature of the picture. Small pieces of marble will roll after the grater, cutting traces in the thickness of the plaster.

4. When the surface formation is completed, use a sharp metal spatula to lightly sand the wall, removing all lumps and the remains of the rolled out grains.

When creating a decorative pattern, you do not need to put too much pressure on the grater to prevent the formation of bursts.

A few nuances

When decorating surfaces of a large area that cannot be plastered in one go, you will have to make sure that the “border” between the frozen coating and the fresh is not visible in the picture. To do this, the wall is divided into vertical sections using masking tape.

As soon as the work reaches this line, the last portion of the plaster is applied with the approach to the adhesive tape. While the solution has not hardened, the adhesive tape comes off with the mixture that fell on it, forming an even cut. The next day, it will be necessary to glue the finished coating exactly to the “cut” line and continue finishing. After staining, the joint will not be visible at all.

Textured bark beetle initially has a clean white color. Its coloring is already done independently - in bulk or after hardening on the wall. The latter option is used more often, since some products are tinted only with the help of special equipment. The bark beetle will look spectacular in the interior of the apartment if it is tinted with glaze compositions in two different colors and coated with wax or shiny varnish.