Technical documentation for maintenance and repair. Service System Technical Documentation

5. FORMS OF REPAIR DOCUMENTATION

5.1. The repair documentation of this Handbook is maximally unified with the documentation of industry-specific “Systems maintenance and repair power equipment". The maintenance of the following forms of repair documentation is envisaged (forms 1-19):

a replaceable journal of identified defects and work to eliminate them; repair log; defect list; cost estimate;

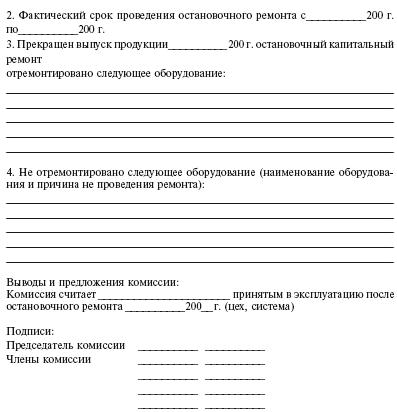

certificate of completion for major repairs;

extradition certificate overhaul;

annual schedule of preventive maintenance;

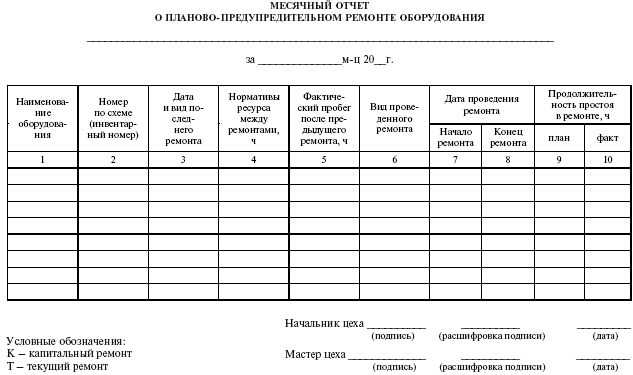

monthly schedule-report-PPR or monthly repair report;

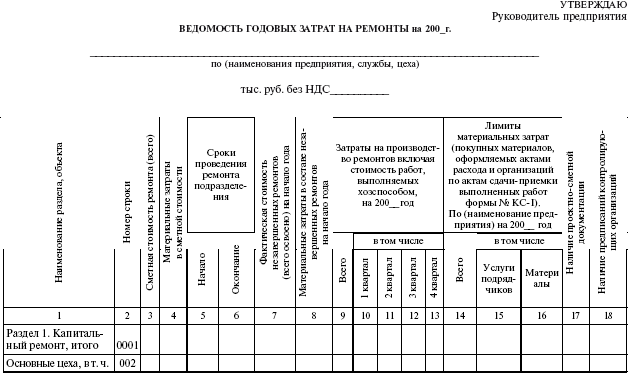

statement of annual repair costs;

an act to change the calendar term of repair;

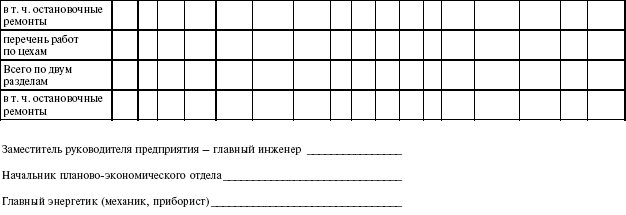

stop repair schedule;

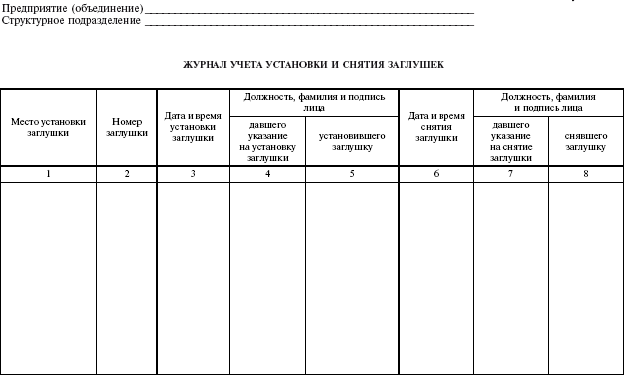

a log of the installation and removal of stubs;

certificate of acceptance of work after a stop repair;

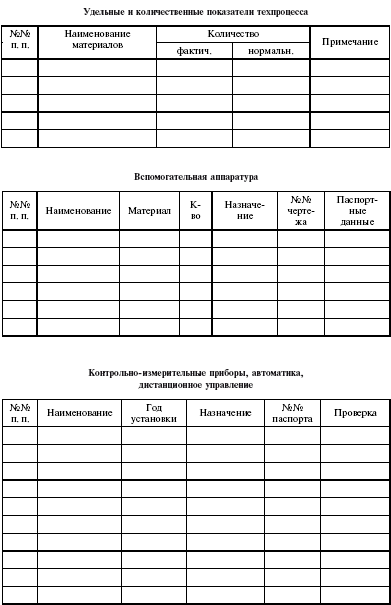

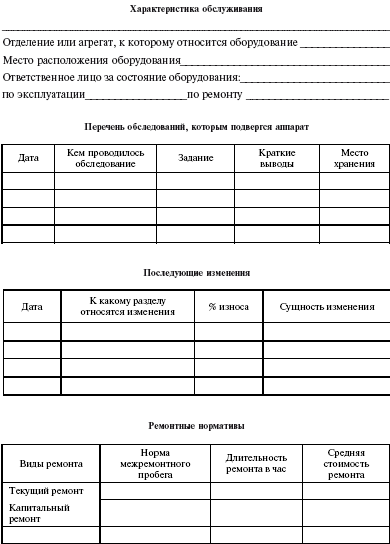

passport of power equipment;

nomenclature of the main equipment of the workshop;

nomenclature of auxiliary equipment;

work permit for repair work;

permission to carry out excavation work on the territory.

5.2. Changes and additions to the previously existing forms of repair documentation were made based on the results of testing the “Unified provision on scheduled preventive repairs of equipment of industrial enterprises of Russia” (Order of the Ministry of Industry and Science of Russia dated 05.05.2003 05.900 114–108).

5.3. The main document by which equipment is repaired is the annual repair schedule (form 7), on the basis of which the need for repair personnel, materials, spare parts, purchased components is determined. It includes every unit of equipment subject to major repairs. The basis for the preparation of the annual schedule is the standards for the frequency of equipment repair given in this Handbook.

5.4. In order to link the timing of repair of power equipment with technological equipment, the annual schedule is agreed with the OGM of the enterprise. If it is necessary to use the services of the chief appliance service, the planned repair dates are agreed with the UCP. The terms of repair of the main equipment, limiting the implementation of the production program, are agreed with the planning department of the enterprise.

5.5. In columns 11–22 of the annual schedule (form 7), each of which corresponds to one month, the symbol in the form of a fraction indicates: in the numerator - the planned type of repair (K - overhaul, T - current), in the denominator - the idle time in hours. Marks on the actual performance of repairs in these columns are made by filling in the planned numbers with a colored pencil.

In columns 23 and 24, respectively, the annual idle time for equipment under repair and the annual fund of working time are recorded.

5.6. The operational document for the repair of equipment is a monthly schedule, a report approved by the chief power engineer of the enterprise for each energy department and site (form 8). Instead of a monthly plan-schedule-report, it is allowed to maintain a monthly repair report (form 8A).

5.7. In this case, the monthly repair planning is carried out in accordance with the annual repair schedule.

5.8. In columns 7-37 (form 8), each of which corresponds to one day of the month, the symbol in the form of a fraction indicates: in the numerator - type of repair (K - overhaul, T - current), in the denominator - its duration (current - in hours , capital - in days).

5.9. A mark on the actual performance of repairs is made after they are completed by a specially designated responsible person in the Unified State Examination, and in the production workshops by the foreman.

5.10. The logbook of installation and removal of plugs (form 14) is maintained by the deputy head of the energy department (head of department, installation, shift supervisor).

5.11. Explanations on the procedure for maintaining the rest of the repair documentation are given above in the relevant sections.

5.12. The repair documentation forms given in this section are typical. Depending on the prevailing repair services enterprises of the specifics of accounting for ongoing repair and maintenance activities that are not regulated by this Handbook (repair inspections, checks, tests, etc.), additional columns (items) may be included in the repair documentation forms.

Form 1

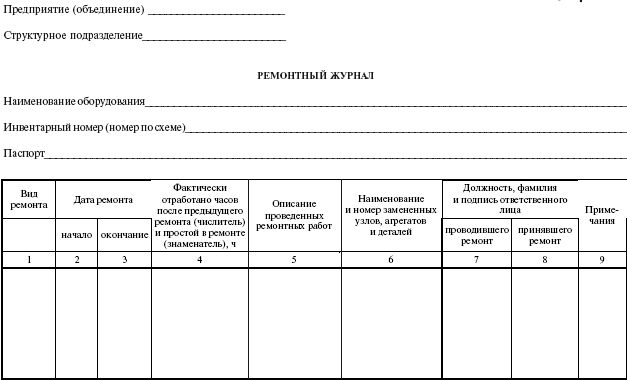

Form 2

Form 3

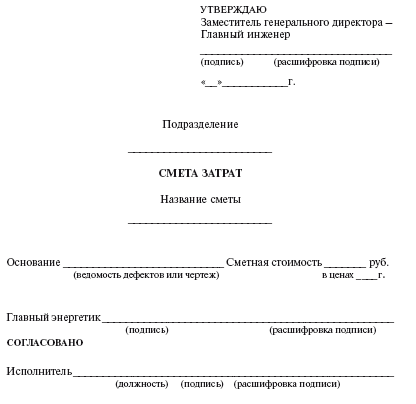

Form 4

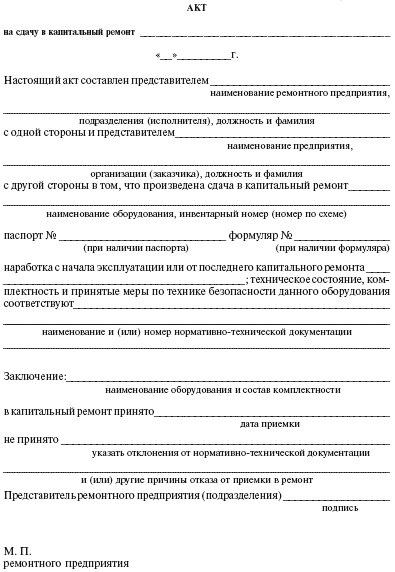

Form 5

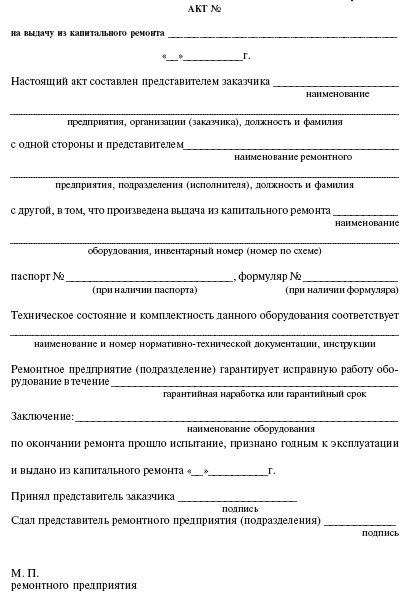

Form 6

Form 7

Form 8

Form 8A

Form 9

Form 10

Form 11

Form 12

Form 13

Form 14

Service System Technical Documentation

The documentation used in the ATP rolling stock service system is classified by the method of receipt, stability, nature of the content and purpose of the information.

Technical documentation includes five main types of documents that are compiled and maintained by the GAAI:

Car face card It is intended for maintenance planning, accounting and analysis of maintenance and repair, accounting downtime. The initial data for its compilation is the frequency of maintenance and daily mileage. The card is filled daily in the production and technical department. The performance of the TP is marked by a record for the corresponding day. At the bottom of the card are recorded units that are replaced. The right side of the card records the total data for the month and year. Records from two sides of the card are made within two years. From the cards you can get the necessary information about the car and the work of production.

Rolling stock maintenance plan report compiled on the basis of a personal card and contains information on the appointment and maintenance. They are filled in by the team leader in the maintenance area.

Maintenance and TP accounting sheet reflects all the technical impacts performed on the car from the moment it enters the zone until the end of work, labor costs, spare parts and materials.

Verification Card Designed to account for work, consumption of materials and spare parts associated with the repair of units in the complex of repair sites. The ticket is issued by the site manager on the basis of the repair task received from the MCC.

Control questions

1. By what criteria is the production of maintenance and car repairs organized?

2. What is meant by production management?

3. What methods of organizing the production of TO and P are used in the ATP?

4. The essence of the organization of production by the method of specialized brigades.

5. The essence of the organization of production by the method of integrated teams.

6. The essence of the organization of production by the aggregate-precinct method.

7. Advantages and disadvantages of various methods of organizing MOT and R.

8. The main tasks of the technical service of the ATP.

9. What units are included in the organizational structure of the technical service.

10. The principles of building the MCC system and its units.

11. Documentation in the ATP rolling stock service system.

Lecture 6

ORGANIZATION OF TECHNICAL MAINTENANCE OF CARS.

6.1 General characteristics of the maintenance process and TR rolling stock.

Calculation of the frequency of maintenance and repair, determination of the frequency of the cyclic mileage of cars. Calculation of the coefficient of technical readiness, determination of the utilization rate of the park. Technical documentation of the service system.

By clicking on the "Download Archive" button, you will download the file you need for free.

Before downloading this file, remember about those good essays, control, term papers, theses, articles and other documents that are unclaimed in your computer. This is your work, it must participate in the development of society and benefit people. Find these jobs and submit to the knowledge base.

We and all students, graduate students, young scientists who use the knowledge base in their studies and work, will be very grateful to you.

To download the archive with the document, in the field below, enter a five-digit number and click the "Download archive" button

Similar documents

Adjusting the frequency of vehicle maintenance and labor standards. Determining the utilization of cars and the annual mileage of cars in the park. Organization of sites current repair trucks.

term paper, added on June 7, 2013

Selection of initial data for the III category of automobile operating conditions. Mileage correction for maintenance, the complexity of maintenance and repair, mileage to overhaul. Calculation of the utilization rate of cars.

term paper added 03/31/2015

Efficiency in the operation of the rolling stock of the fleet. Methods of grouping operations by type of maintenance, in order to reduce material and labor costs. Determination of the coefficient of technical readiness of vehicles.

test, added 09/22/2011

Calculation of the annual production program. Determination and adjustment of the resource run. Calculation of the utilization rate of cars. The choice and justification of the method of the organization of the technological process of maintenance and repair.

term paper, added 11/08/2012

Technical specifications cars (ZIL-130, GAZ-53A). Calculation of the frequency of maintenance and mileage before overhaul. The mode of operation of maintenance and repair zones, branches and workshops. Method of organizing production.

term paper, added 1/27/2016

Organization of the technological process, diagnosis, maintenance and repair of the steering. Calculation of the coefficient of technical readiness and the total annual mileage of the car. Occupational health and safety at a taxi company.

thesis, added 06/13/2015

The work of rolling stock of automobile transport. Calculation of the production program of the complexity of maintenance and repair. Determination of total annual mileage and vehicle utilization. The choice of production equipment.

term paper, added 03/22/2013

Description of the enterprise and its repair base. A study of the composition of the car fleet. Adjusting the frequency and complexity of maintenance and repair of vehicles, the calculation of the production program. Analysis of investments and expenses.

thesis, added 05/10/2013